6 Pallet Shipping Moves That Cut LTL Damages

Freight damage costs businesses $1,511 per incident. Most are preventable. Here's how to protect your shipments and your bottom line.

When you're shipping pallet freight across Canada and the USA, damaged shipments and surprise fees add up fast. Studies show up to 11% of unit loads arrive damaged at distribution centers—often because freight isn't correctly secured on the pallet itself.

We've helped thousands of shippers minimize both damage claims and surprise fees. These seven proven strategies can reduce your total freight costs by 10-20% through fewer damages, disputes, and accessorial charges.

Quick Navigation

1. Build Your Pallets for Multiple Handlers (Not Just One Trip)

Your pallet will be handled at least five times: loaded at your dock, moved to a terminal, transferred to a long-haul trailer, handled at a second hub, and finally delivered. Each touchpoint is an opportunity for damage.

Pallet Building Essentials

- ✓ Use sturdy standard pallets (GMA-style or Engineered Molded Wood for heavier items)

- ✓ Stack evenly to distribute weight across the entire surface

- ✓ Avoid overhang – boxes extending past pallet edges get crushed

- ✓ Keep height reasonable – taller loads tip more easily

Key fact: Corrugated boxes can lose up to 71% of their strength in high-humidity conditions—critical for Canada-USA cross-border shipments.

2. Secure Loads Properly Inside and Out

Internal Securement (On Your Pallet)

- Void fill: Airbags, foam blocks, or kraft paper to prevent shifting

- Tier sheets: Corrugated pads between layers to spread weight

- Anti-slip sheets: Prevent sliding during braking

- Corner boards: Protect edges from wrap cutting

External Securement (In the Trailer)

Quality carriers secure mixed loads properly with load bars and strategic placement. You can help by:

- Clearly labeling fragile pallet freight

- Marking top-load limits

- Using standard pallet sizes for efficient trailer configuration

3. Master the Art of Stretch Wrapping

Proper Technique:

- Start at the base – wrap around the pallet itself, not just the freight

- Overlap by 50% as you spiral upward

- Apply tension for compression without crushing

- Cover the top to protect from dust and moisture

Pro Tip: Loose packages are a top cause of damage claims. Tight wrapping saves money.

4. Choose Carriers Based on Performance, Not Just Price

Not all LTL carriers handle freight equally. Focus on these metrics:

| Metric | Why It Matters | What to Look For |

|---|---|---|

| Claims Ratio | Shows handling quality | Under 1% is excellent |

| Equipment Quality | Reduces vibration damage | Air-ride suspension, modern docks |

| On-Time Performance | Rushed freight = rough handling | 95%+ on-time delivery |

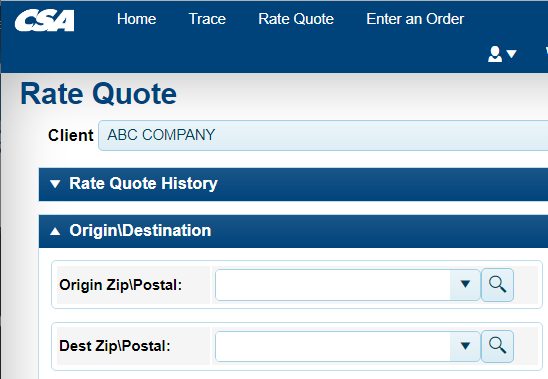

CSA Transportation maintains a 99.8% claims-free delivery rate through 15 strategically positioned terminals and careful handling procedures.

5. Consolidate Shipments When It Makes Sense

Simple math: Ship 3 pallets together instead of separately = 1 pickup/delivery instead of 3 = fewer touches = less damage.

When to Consolidate:

- Multiple orders to same region

- Flexible delivery schedule

- Uniform pallet builds possible

- Volume discounts apply

When Not to Consolidate:

- Time-critical orders

- Widely spread destinations

- Storage costs exceed savings

- Mixed freight types

6. Document Everything and Audit Regularly

Essential Documentation Checklist

| ☐ Complete BOL | Exact dimensions, weight, stackable status, special handling |

| ☐ Pickup photos | Wide shot + close-ups of wrap, labels, protection |

| ☐ Delivery receipt | Note exceptions immediately on POD |

| ☐ Weight tickets | Protect against reweigh variances |

Monthly Audit Points

- Compare billed vs. tendered specs

- Track recurring accessorial charges

- Identify damage patterns by lane/product

- Verify rate applications against quotes

7. Implement Your Action Plan

Start Tomorrow:

- Audit your pallet standards – Define stackable criteria, max height, and overhang limits

- Tighten your build process – Add top caps, edge boards, eliminate overhang

- Talk to your carrier – Ask for lane-specific tips and common fee triggers

- Start photographing shipments – Cost: $0. Value: Priceless when you need proof

Ready for Pallet Rates?

Join shippers achieving 99.8% damage-free delivery with CSA Transportation.

Get a Fast Quote15 terminals across Canada & USA • Same-day pickup • Daily scheduled departures

Frequently Asked Questions

About CSA Transportation: Serving shippers across Canada and the USA with 15 terminals, same-day pickup, and scheduled daily departures. Our pallet-based pricing and 99.8% claims-free delivery rate help businesses reduce shipping costs while protecting their freight.

Contact our team for a freight audit and personalized recommendations for your shipping needs.