- Home

- What is a Supply Chain Network and How Does it Work?

What is a Supply Chain Network and How Does it Work?

Keeping supply chains moving and customers happy since 1986!

Let the CSA Network help you for shipments from a single pallet to a full load!

We have just completed a major expansion in Toronto that has doubled the size of our high-speed LTL terminal. Located on 5 acres, this facility with 25 loading doors significantly enhances transit times across the CSA Network. Learn more

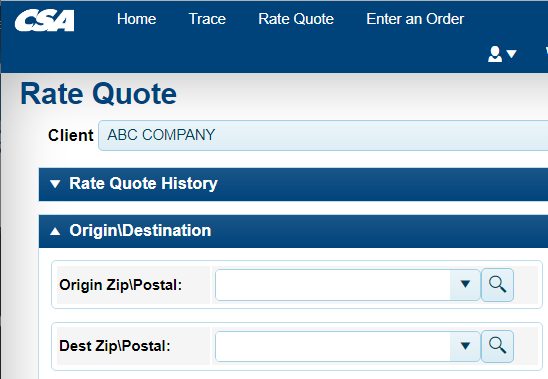

CSA ONLINE: Access our tariff and get highly competitive pallet rates for 90% of all postal/ZIP codes in Canada/USA serviced directly through our network. Instant freight quotes, order booking, document access and shipment tracking. Learn More

Nous nous excusons la traductions en françaises sera bientôt disponible.

Shipping Documents

-

Bill of Lading (BOL)

Download a Fillable PDF -

Application for Credit

Download a Fillable PDF -

Customs Invoice (CBSA)

How to & Download -

Commercial Invoice (CI)

How to & Download -

Certificate of Origin

Download a Fillable PDF -

Freight Claim Form

Download a Fillable PDF

The documents here are mostly PDF forms for download. If you are looking for POD's or other scanned documents related to your shipment please request access to CSA's online portal here.

For best results with the PDF forms in the downloads tab please first save the file and then open it with the latest version of Adobe Reader.

These files have been designed as fillable forms where data can be entered and, if necessary partially completed and saved, to reuse later on a similar shipment. For example if you have regular orders between the same locations you can download a Bill of Lading and save it with all the required location information.

To take advantage of this functionality please right click the blue "download" text and save the file to your computer.

Note: If you are attempting to view any of these documents in your browser's PDF viewer (by clicking on them directly), you may not be able to make use the fillable form fields and the save functionality. Check if your browser supports the adobe plugin here and follow the steps to add the adobe plugin to your browser. If you can't get the in-browser forms to work just right click and download the PDF and open with Adobe Reader.

Please contact us if you have additional questions or feedback.